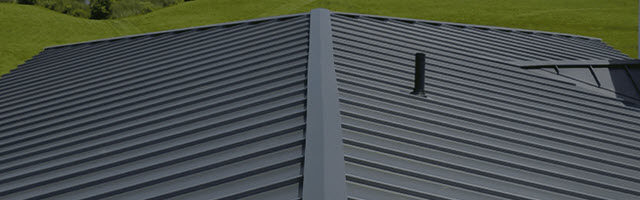

Pre-Painted Aluminum

PVDF

Pre-Painted Aluminum (PVDF) is offered by Armour Cladding. Aluminum coil and flat sheet in the most popular colors in the market today. The 3105-H14 aluminum substrate provides an excellent surface for paint, has good cold workability, is weldable, and has very good corrosion resistance. Our pre-painted PVDF aluminum carries industry competitive warranties and you can be confident the quality and service you receive will be world-class.

PVDF paint systems are developed using specialized ceramic pigments combined with fluoropolymer resins to create high-end coatings for metals. PVDF paint systems typically come with a standard 30-year limited warranty offered by the paint manufacturer.

PVDF pre-painted aluminum has been the go-to product for architects and designers around the world to achieve beautiful, vibrant colors with the added benefits of flexibility and durability in a lightweight product, that only aluminum can provide.

Benifits

Lightweight

Aluminum products are approximately one third the weight of steel.Gloss & Color Retention

Gloss and color remain intact longer as compared to other paint systems.- Harsh Weather Resistance

Performs better in harsh environments. AAMA 2605-13 Standard

Our Pre-Painted Aluminum Series meets AAMA 2605-13 requirements, so you can rest assured our product will meet all standard specifications for project.

Benifits

Lightweight

Aluminum products are approximately one third the weight of steel.Gloss & Color Retention

Gloss and color remain intact longer as compared to other paint systems.- Harsh Weather Resistance

Performs better in harsh environments. AAMA 2605-13 Standard

Our Pre-Painted Aluminum Series meets AAMA 2605-13 requirements, so you can rest assured our product will meet all standard specifications for project.

End-Use Applications

PVDF pre-painted aluminum is best suited for high-end applications such as commercial or residential siding, pre-engineered buildings, architectural wall panels, facades, and other applications where durability and long-lasting performance are required.

End-Use Applications

Aluminized Steel, due to its inherent benefits, is commonly used in manufacturing mufflers, fireplaces, incinerators, heat inductors as well as other applications where heat resistance is required. Other applications of Aluminized Steel include corrugated roofing and siding, grain bins, drying ovens, and air-conditioner condenser housings.

Trusted Partners

Armour Cladding is proud to have created several stable and long-term relationships with various partners to ensure we provide you with the greatest product and value possible.

Trusted Partners

Armour Cladding is proud to have created several stable and long-term relationships with various partners to ensure we provide you with the greatest product and value possible.