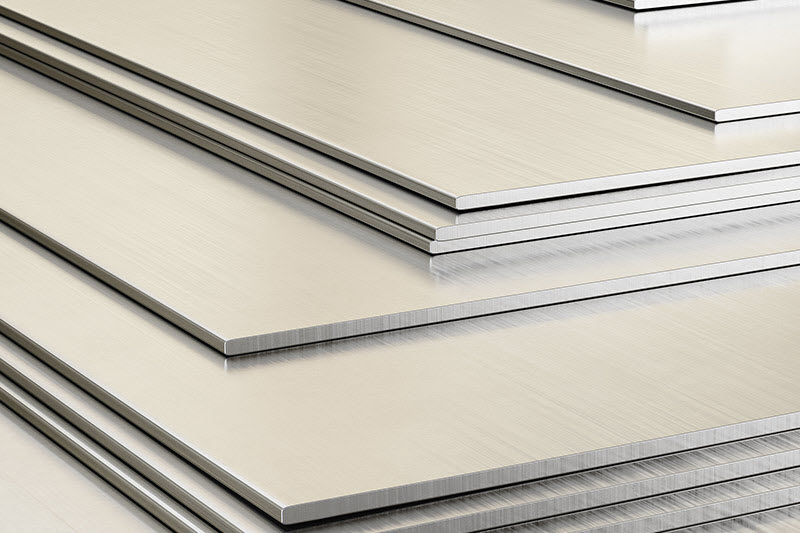

Aluminum Sheet Metal & Plates

Aluminum sheet metal & plates are made from aluminum alloy. They are the most common forms of industrial aluminum, which are widely used in packaging, construction, and aerospace industries. They are available in different forms, including diamond sheet, expanded sheet, perforated sheet, coated sheet, or painted plate. Sheet and plate are made from the same metal, but the sheet is thinner than the plate. It comes in many different thicknesses, ranging from 0.5mm up to 6.0mm. Both of these materials can be used for many applications, including roofing, gutters, and siding. What is the difference between aluminum sheet and plate? Here’s a brief explanation of the two types of aluminum.

| Standard | JIS, AiSi, ASTM, GB, DIN, EN |

| Thickness | 0.8 mm – 40 mm |

| Length | 1220 mm – 3000 mm, Custom |

| Width | 30 mm – 1850 mm, Custom |

| Tolerance | ±1% |

| SS Grade | 1050, 1060, 1100, 3003, 3105, 5052, etc… |

| Technique | Cold Rolled |

| Finish | Powder Coating, Brushing, Sandblasting, etc… |

| Colours | Champagne, Black, Blue, Silver, Gold, Rose Gold, etc… |

| Edge | Mill Edge / Silt Edge |

| Applications | Architectures, Decorations, Appliance, Vehicles & Aircraft |

| Packaging | PVC/Wooden Package & Waterproof Paper |

| Standard JIS, AiSi, ASTM, GB, DIN, EN |

| Thickness 0.8 mm – 40 mm |

| Length 1220 mm – 3000 mm, Custom |

| Width 30 mm – 1850 mm, Custom |

| Tolerance ±1% |

| SS Grade 1050, 1060, 1100, 3003, 3105, 5052, etc… |

| Technique Cold Rolled |

| Finish Powder Coating, Brushing, Sandblasting, etc… |

| Colours Champagne, Black, Blue, Silver, Gold, Rose Gold, etc… |

| Edge Mill Edge / Silt Edge |

| Applications Architectures, Decorations, Appliance, Vehicles & Aircraft |

| Packaging PVC/Wooden Package & Waterproof Paper |

Alloy Grades for Aluminum Sheets & Plates

There are different alloy grades for aluminum sheet and plate. The most common ones are 6061 and 6063. These alloys have the best overall properties. 6061 is used most often in building profiles. Its machinability, resistance to corrosion, and strength-to-weight ratio make it an excellent choice for aerospace applications. However, 6063 and 6082 have low corrosion resistance and are commonly used in structural applications.

| 1000 Series (pure aluminium) |

1050, 1060,1070, 1100, 1200, etc… |

| 2000 Series (aluminium-copper alloy) |

2011, 2014, 2017, 2024 etc… |

| 3000 Series (aluminium-manganese alloy) |

3003, 3004, 3005, 3104, 3105, 3A21, etc… |

| 4000 Series (aluminium-silicon alloy) |

4A01, 4045, 4343, etc… |

| 5000 Series (aluminium-magnesium alloy) |

5005, 5052, 5083, 5086, 5754, etc… |

| 6000 Series (aluminium-magnesium-silicon alloy) |

6061, 6063, 6082, 6A02, etc… |

| 7000 Series (aluminium-magnesium-silicon alloy) |

7075, 7005, 7050, ect… |

| 8000 Series (aluminium-foil alloy) |

8006, 8011, 8079, etc… |

Alloy 1100 is the most commercially pure type of aluminum. It has a high mechanical strength and is ductile. It is also non-heat-treatable. These alloys are used in the food processing and chemical industries. Aluminum 2024 is one of the highest-strength alloys. It is used in structural and automotive applications. 2024 sheet is commonly clad with some elements for corrosion resistance. It can be molded and forged in annealed condition.

Alloy Grades for Aluminium Sheets & Plates

There are different alloy grades for aluminum sheet and plate. The most common ones are 6061 and 6063. These alloys have the best overall properties. 6061 is used most often in building profiles. Its machinability, resistance to corrosion, and strength-to-weight ratio make it an excellent choice for aerospace applications. However, 6063 and 6082 have low corrosion resistance and are commonly used in structural applications.

| 1000 Series (pure aluminium) 1050, 1060,1070, 1100, 1200, etc… |

| 2000 Series (aluminium-copper alloy) 2011, 2014, 2017, 2024 etc… |

| 3000 Series (aluminium-manganese alloy) 3003, 3004, 3005, 3104, 3105, 3A21, etc… |

| 4000 Series (aluminium-silicon alloy) 4A01, 4045, 4343, etc… |

| 5000 Series (aluminium-magnesium alloy) 5005, 5052, 5083, 5086, 5754, etc… |

| 6000 Series (aluminium-magnesium-silicon alloy) 6061, 6063, 6082, 6A02, etc… |

| 7000 Series (aluminium-magnesium-silicon alloy) 7075, 7005, 7050, ect… |

| 8000 Series (aluminium-foil alloy) 8006, 8011, 8079, etc… |

Alloy 1100 is the most commercially pure type of aluminum. It has a high mechanical strength and is ductile. It is also non-heat-treatable. These alloys are used in the food processing and chemical industries. Aluminum 2024 is one of the highest-strength alloys. It is used in structural and automotive applications. 2024 sheet is commonly clad with some elements for corrosion resistance. It can be molded and forged in annealed condition.

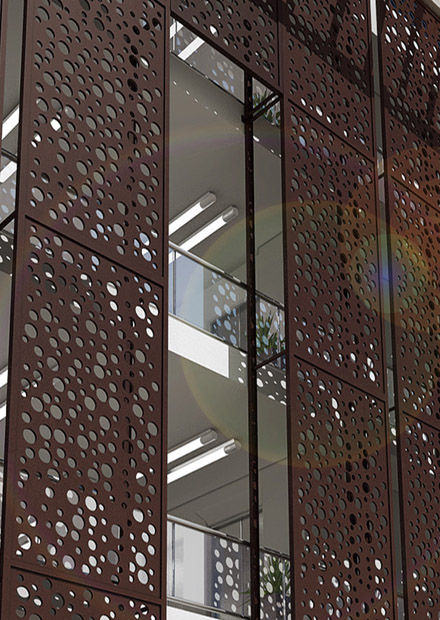

Applications For Aluminium Sheet & Plate

Aluminum sheet metal & plate are largely used for architectural metal works such as facade cladding, siding, roofing, fencing, ceiling, dividing screen, etc. The process of manufacturing aluminum sheet involves pressing raw aluminum between high-powered rollers. The resulting sheets are flattened and become thinner and longer than before. These sheets are a valuable resource for modern industry and are acquired by all major markets. One of the most common products made from aluminum sheet is the aluminum composite plate.

Facade Clading

Roofing

Screens

Ceilings

Mashrabiya

Differences Between Aluminum Sheets & Plates

The difference between aluminum sheets and plates is primarily due to its thickness. For example, aluminum sheet is thin and reshapable, while aluminum plate is a sheet with a thicker profile. The thickness of aluminum sheet varies, as it’s manufactured by rolling it between rolls under pressure. In general, the thinner end of the scale is softer than the thicker end.

Aluminum Sheet

The thickness range of aluminum sheets is generally between 0.8mm and 6.0mm, which is thinner than plate. Aluminum sheet is durable and lightweight, it has distinct applications. Aluminum sheet is generally less durable than plate, but the thickness of aluminum sheet depends on its application. Aluminum sheet and plate are also useful in the construction industry, such as building fences and siding.

Aluminum Plate

The thickness of aluminum plate is up to 6.0mm, and its most applications include the aerospace, transportation, and military industries. Due to their resistance to corrosion, aluminum alloys are widely used in spacecraft fuel tanks and storage tanks. They are also used in military vehicles and armor for military vehicles. Ultimately, aluminum is used to make high-quality, lightweight, and durable items. So, if you’re wondering how aluminum can benefit your business, don’t hesitate to contact us.

When you are comparing two types of aluminum, it’s important to understand the differences between the two products. Aluminum sheet and plate are both used in a wide range of applications, including roofing and building construction. If you’re unsure of which type you need, keep reading to find out more about them. Besides roofing, you can also use aluminum sheet for other purposes, including cooking utensils and sports equipment.

What To Consider When Buying Aluminum Sheets & Plates

If you’re planning to buy aluminum sheet and plate for your commercial project, you might be wondering what you should look for in a supplier. Not all suppliers are created equal – quality and precision are essential. Make sure you find a supplier that has extensive experience and expertise in this field. Below are a few of the most important factors to look for in a supplier. Listed below are some tips for choosing an aluminum supplier for your project.

Thickness

The thickness of the material you’re purchasing is essential for durability. Luckily, aluminum sheet materials are a popular choice for many industries and are easy to clean. However, the best way to make sure you’re buying the right type of material is to look for a supplier that can provide the material data you need to make the decision easier. Aluminum sheet materials are typically six mm thick. At the thinner end, these materials qualify as foil.Price

Price is an important consideration when buying aluminum sheet, but it is even more important when you’re buying wholesale. While there are some manufacturers offering aluminum sheet at ridiculously low prices, these are often of poor quality. Look for a supplier that offers reasonably priced sheets while still leaving you room for discount offers. Lastly, look for good reputation. Buying aluminum sheet from a reliable supplier will ensure the highest quality for the lowest price.Appearance

The material’s appearance and feel will impact its durability. A high-quality aluminum sheet should match the appearance of its surroundings. Raw aluminum sheeting is also durable and suitable for rivet, plate, and welding. Among its other benefits, aluminum sheeting is a cost-effective and user-friendly choice compared to stainless steel.Microstructure

The microstructure of aluminum sheet depends on the type of alloy it is made of. TRC sheets have coarse a-Al grains while MCTRC sheet has fine equiaxed grains. Whether you need an aluminum sheet or plate for a specific application, make sure you check its thickness before buying it. You should also look for a company that can deliver your specific needs.Surface condition

The surface condition of aluminum sheet is crucial in resistance spot welds. Variations in the oxide film between electrodes and the plate interface affect the resistance of the spot welds. You can test the resistance by clamping the plate between two electrodes and applying a preset current of between 10 to 15 A. The voltage resulting from this measurement is used to calculate the resistance using Ohm’s Law. A well-clean plate has a resistance of 10-100 microhms or less.Quality

While buying aluminum sheet & plate, make sure you choose a company that offers multiple grades. Some aluminum grades are better than others. For example, 6082 aluminum is a medium strength structural alloy. It is highly corrosion resistant, which is important for force-intensive applications. This grade is also an excellent choice for aerospace applications and automobile structures. Finally, 6082 aluminum is a superb reflector, which makes it ideal for heat-forwarding lamps, lamp reflectors, and outdoor walkways.

Thickness

The thickness of the material you’re purchasing is essential for durability. Luckily, aluminum sheet materials are a popular choice for many industries and are easy to clean. However, the best way to make sure you’re buying the right type of material is to look for a supplier that can provide the material data you need to make the decision easier. Aluminum sheet materials are typically six mm thick. At the thinner end, these materials qualify as foil.Price

Price is an important consideration when buying aluminum sheet, but it is even more important when you’re buying wholesale. While there are some manufacturers offering aluminum sheet at ridiculously low prices, these are often of poor quality. Look for a supplier that offers reasonably priced sheets while still leaving you room for discount offers. Lastly, look for good reputation. Buying aluminum sheet from a reliable supplier will ensure the highest quality for the lowest price.Appearance

The material’s appearance and feel will impact its durability. A high-quality aluminum sheet should match the appearance of its surroundings. Raw aluminum sheeting is also durable and suitable for rivet, plate, and welding. Among its other benefits, aluminum sheeting is a cost-effective and user-friendly choice compared to stainless steel.Microstructure

The microstructure of aluminum sheet depends on the type of alloy it is made of. TRC sheets have coarse a-Al grains while MCTRC sheet has fine equiaxed grains. Whether you need an aluminum sheet or plate for a specific application, make sure you check its thickness before buying it. You should also look for a company that can deliver your specific needs.Surface condition

The surface condition of aluminum sheet is crucial in resistance spot welds. Variations in the oxide film between electrodes and the plate interface affect the resistance of the spot welds. You can test the resistance by clamping the plate between two electrodes and applying a preset current of between 10 to 15 A. The voltage resulting from this measurement is used to calculate the resistance using Ohm’s Law. A well-clean plate has a resistance of 10-100 microhms or less.Quality

While buying aluminum sheet & plate, make sure you choose a company that offers multiple grades. Some aluminum grades are better than others. For example, 6082 aluminum is a medium strength structural alloy. It is highly corrosion resistant, which is important for force-intensive applications. This grade is also an excellent choice for aerospace applications and automobile structures. Finally, 6082 aluminum is a superb reflector, which makes it ideal for heat-forwarding lamps, lamp reflectors, and outdoor walkways.

Benefits Of Aluminum Sheet Metal & Plates

If you are considering making the transition from wood to aluminum, you may be wondering about the advantages of using this material. In this article, we’ll review the benefits of aluminum sheet metal, including its sturdiness, easy fabrication, and eco-friendliness. You will also find out how corrosion resistance and ease of maintenance make it an ideal choice. Keep reading to learn more! Here are five reasons to use aluminum sheet metal and plate in your construction project.

Decorative Purposes

Decorative aluminum sheet metal and plate are thin pieces of aluminum that are typically chemically treated to produce various colors. They are widely used in the aerospace industry and transportation industries due to their light weight and resistance to corrosion. The thin sheets are also great for decorative purposes, since they can be easily cleaned and maintained.Fabricability

The advantages of aluminum sheet metal fabrication are numerous. Its light weight, low cost, and easy machining make it easy to process. It is widely used for a variety of applications, including automotive parts. In addition to its ease of fabrication, aluminum is inexpensive to purchase and maintain. It can be easily cut and shaped, and bending and welding are the most common processes. Below are some of the benefits of aluminum sheet metal fabrication.Eco-Friendly

There are numerous benefits to using aluminum for your projects. It is recyclable and has a very low carbon footprint. Over 90% of the primary aluminum is produced using renewable hydro-electric power. It is also extremely lightweight, making it easy to manipulate into any shape. An aluminum sheet the size of a large football field can weigh nine tons. It can be as thin as construction paper. And the waste from manufacturing a giant sheet of aluminum can be recycled into new rolls.Corrosion Resistance

Aluminum sheet and plate is available in a variety of grades, including 5052-H32, which has 99% minimum purity and is a versatile material. Its excellent corrosion resistance, good weldability, and high fatigue strength make it a superior choice for many applications. These grades are commonly used for pressure vessels and storage tanks, and are typically packaged in 2000-pound skids with paper interleads.Cost-Effective

Increasing demand for materials such as aluminum increases overall production costs. In less developed countries, such as China, investment in infrastructure increases demand for aluminum. Increasing production costs in the United States, however, have caused the price of aluminum to increase, especially in the automotive industry. Despite this, the price of Chinese aluminum is still relatively inexpensive. However, the economic impact of this shift in production costs has been modest.

Decorative Purposes

Decorative aluminum sheet metal and plate are thin pieces of aluminum that are typically chemically treated to produce various colors. They are widely used in the aerospace industry and transportation industries due to their light weight and resistance to corrosion. The thin sheets are also great for decorative purposes, since they can be easily cleaned and maintained.Fabricability

The advantages of aluminum sheet metal fabrication are numerous. Its light weight, low cost, and easy machining make it easy to process. It is widely used for a variety of applications, including automotive parts. In addition to its ease of fabrication, aluminum is inexpensive to purchase and maintain. It can be easily cut and shaped, and bending and welding are the most common processes. Below are some of the benefits of aluminum sheet metal fabrication.Eco-Friendly

There are numerous benefits to using aluminum for your projects. It is recyclable and has a very low carbon footprint. Over 90% of the primary aluminum is produced using renewable hydro-electric power. It is also extremely lightweight, making it easy to manipulate into any shape. An aluminum sheet the size of a large football field can weigh nine tons. It can be as thin as construction paper. And the waste from manufacturing a giant sheet of aluminum can be recycled into new rolls.Corrosion Resistance

Aluminum sheet and plate is available in a variety of grades, including 5052-H32, which has 99% minimum purity and is a versatile material. Its excellent corrosion resistance, good weldability, and high fatigue strength make it a superior choice for many applications. These grades are commonly used for pressure vessels and storage tanks, and are typically packaged in 2000-pound skids with paper interleads.Cost-Effective

Increasing demand for materials such as aluminum increases overall production costs. In less developed countries, such as China, investment in infrastructure increases demand for aluminum. Increasing production costs in the United States, however, have caused the price of aluminum to increase, especially in the automotive industry. Despite this, the price of Chinese aluminum is still relatively inexpensive. However, the economic impact of this shift in production costs has been modest.

Standard Sizes For Aluminum Sheet & Plates

When looking for a supplier of aluminum sheets & plates, it’s important to know the standard sizes available for the different types of materials. Despite the differences in thickness, aluminum sheets are essentially the same. They are thicker than foil but thinner than 6mm. There are several different types of aluminum sheets & plates available on the market, including extruded and forged metals. While they are not interchangeable, these materials are typically used for similar applications.

Aluminum sheet is one of the most common types of aluminum material. It is used in almost all areas of the aluminum industry, from packaging to aerospace and food processing. It’s also commonly used in household appliances, cookware, and packaging. While aluminum is highly corrosion-resistant, different grades may not have the same properties. This means that some types of aluminum sheet may have different properties than others. As a result, it’s important to understand which type of aluminum sheet is best for your particular application.

Trusted Partners

Armour Cladding is proud to have created several stable and long-term relationships with various partners to ensure we provide you with the greatest product and value possible.

Trusted Partners

Armour Cladding is proud to have created several stable and long-term relationships with various partners to ensure we provide you with the greatest product and value possible.