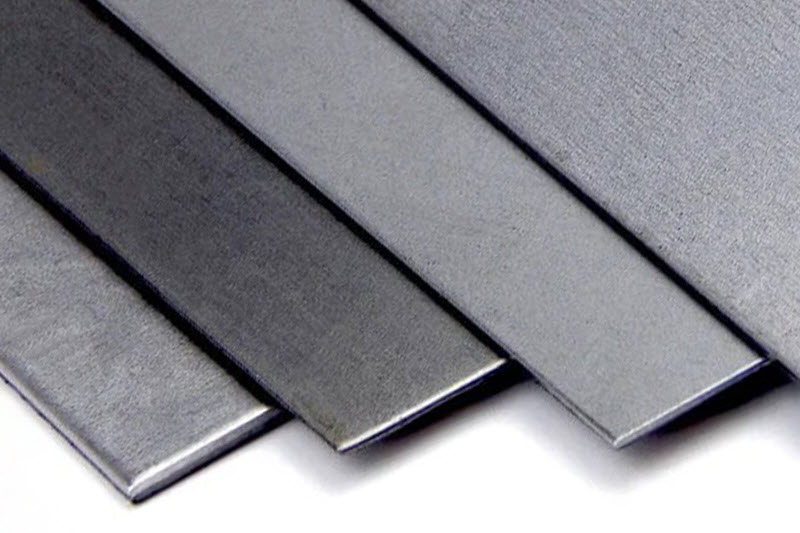

Stainless Steel Plates

Stainless steel plates / sheets provide durability and corrosion resistance for long-lasting use, they have the capability of withstanding rain, acid, salt, and other corrosive substances. As stainless steel sheet has high strength, so it’s strong enough to be utilized without much thickness, helping save much cost on material consumption. Stainless steel is an environmental-friendly material as its scrap is totally reusable & recyclable. In addition to some beneficial properties, the cost of stainless steel sheet is reasonable to afford, and it’s also ideal for easy fabrication, such as cutting, forming, and joining, so it’s a versatile material to be widely used in architecture, decoration, electronic appliance, kitchenware, marine, chemical, and many other applications.

| Type | Stainless Steel Sheet / Stainless Steel Plate |

| Thickness | 0.2 – 50mm |

| Length | 2,000mm, 2,438mm, 3,000mm, 5,800mm, 6,000mm, 12,000mm, etc… |

| Width | 40mm-600mm, 1,000mm, 1,219mm, 1,500mm, 1,800mm, 2,000mm, 2,500mm, 3,000mm, 3,500mm, etc… |

| Standard | ASTM, AISI, JIS, DIN, EN |

| Surface | BA / 2B / NO.1 / NO.4 / 4K / HL / 8K / Embossed |

| Application | Architecture, Decoration, Kitchenware, Home Appliance, Medical Equipment, Petroleum, etc… |

| Certification | ISO, SGS |

| Technique | Cold Rolled / Hot Rolled |

| Edge | Mill Edge / Silt Edge |

| Quality | Mill Test Certificate supplied with the shipment, third part inspection is acceptable |

| Grade (ASTM/UNS) | 201, 304, 304L, 321, 316, 316L, 317L, 347H, 309S, 310S, 904L, S32205, 2507, 254SMOS, 32760, 253MA, N08926 |

| Grade (EN) | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4438, 1.4539, 1.4547, 1.4529, 1.4562, 1.4410, 1.4878, 1.4845, 1.4828, 1.4876, 2.4858, 2.4819 |

| Technique | Surface Finish |

Grade Series |

Thickness (mm) |

Width (mm) | |||||

| 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 | ||||

| Hot Rolled | No.1 / 2E | 201/202/304 | 2.2-12.0 | ||||||

| Cold Rolled | 2B | 201/304 | 0.25-3.0 | ||||||

| 410S/430 | 0.25-2.0 | ||||||||

| No.4 / Hairline / SB | 201/304 | 0.22-3.0 | |||||||

| 410S/430 | 0.25-2.0 | ||||||||

| BA | 201/304 | 0.2–1.8 | |||||||

| 410S/430 | 0.25-2.0 | ||||||||

| 2BA | 410S/430 | 0.25-2.0 | |||||||

Common Grades

There are numerous grades of stainless steel sheets are available on the market, they are generally defined according to their manufacturing processes and alloying composition. They all have common features such as durability and resistance to rust, corrosion, and stain. However, there are still a few slightly different properties between these grades. There are two common grades of stainless steel sheets (304 & 316) that we commonly used for your projects, you need to consider some factors below:

304 Stainless Steel Sheet

A stainless steel sheet with 304 grade is perfectly used for a wide variety of general-purpose and light-duty applications. It highly contains chromium and nickel elements, which help enhance its resistance to water, humidity, and oxidation. The properties of 304 stainless steel sheet metal include:

Resistant to rust and oxidation

Easy to form and fabricate

Not magnetizable

- Durable

In addition to commonly being used for architectural & decorative projects, 304 stainless steel is perfectly ideal for food and healthcare applications, as it can resist most oxidizing acids and some corrosive substances. However, 304 stainless steel comes with one weakness, it will gradually get corroded once locate in chloride environments, or in coastal areas with a salt atmosphere. Chloride irons can cause some corroded areas, defined as “pitting”, which can spread under the protective layer of chromium to damage internal structures.

Difference Between Stainless Steel Sheet & Plates

Stainless steel sheet & plates are absolutely not the same, they are typically different in their thickness. The more the thickness, the stronger the strength, different thickness is used for a different purpose. Below are the properties for stainless steel sheet and plate:

- Stainless Steel Sheets

Stainless steel sheets generally feature a thickness not more than 6mm, it’s usually utilized for architectural structures and decorative material without extra durability requirements. Stainless steel sheet comes with corrosion resistance and is well suited for cladding, roofing, railing, and ceiling.

- Thickness is generally not more than 6mm

- Thickness is less than stainless steel plate

- Light weight is usually for architectural and residential applications

- Stainless Steel Plate

The thickness of stainless steel plate is typically more than 6mm, and it’s usually applied in purposes where required high durability and strength are more than the weight requirement. It is used in architectural structures and industrial applications where durability is required to pass strength & tenacity testing.

- Thickness is generally more than 6mm

- Thickness is more than stainless steel plate

- High tensile strength and durability for heavy-duty applications

Compositions Of Stainless Steel Sheets

The major material of stainless steel sheet is iron, which is the plain steel simply consisted of steel and carbon. For optimizing the properties of steel, we can melt the carbon steel together with some other elements, such as chromium, molybdenum, silicon, nickel and some additives. Such an alloy of iron is more resistant to rust than the carbon steel, as the added elements mixed together can form an inert oxide layer that can protect the surface from corrosion and stain.

The capability of resistance to oxide or corrosive substances is effected by the proportions of alloy elements including steel, chromium, molybdenum, nickel, etc… Which means that different types of stainless steel are determined by the ration of steel to other elements. In addition to the resistance, the difference of proportion also effects other mechanical properties such as strength, ductility, melting point, etc… Different types of stainless steel alloys are classified by different ratios of their alloying elements. these alloy compositions are assorted to different grades of stainless steel such as 201, 304, 316, 410S, 430, and so on.

Benefits Of Stainless Steel Sheet

There is a wide range of metal materials commonly used in architectural sheet metal projects, if you’re wondering which type of metal you should purchase for your home improvement or other applications, consider stainless steel sheet! It is one of the most popular and versatile types, as we can find some benefits that are unique and unparalleled to increase the added value of the projects. The most significant properties of stainless steel sheets are durability and corrosion resistance, and their sleek and unfailing appearance. Now let’s explore some more different benefits of it and see if it would be proper for your applications.

- High Strength & Durability

Stainless steel sheet provides high resistance to impact and wear due to its high strength and toughness. Without much material being used, it can achieve the durable effect, and its shape and form can be kept in good condition even in great pressure. At high or low temperatures. stainless steel comes with low susceptibility to brittleness to allow it to be used without limit. Its outstanding malleability make it easy to be fabricated and formed. - Corrosion & Rust Resistant

As stainless steel sheet has a unique alloying combination that can extremely resist to corrosion and prevent rust. The element of chromium inside is the essential factor that provides stainless steel this property. The invention or discovery of stainless was regarded as the major breakthrough in steel development. Stainless steel can be made with various alloying proportions to provide different properties and grades for different purposes. For example, some types of stainless steel consist of certain amount of molybdenum for resisting to industrial acids and alkaline with high corrosion, and some types are particularly used for coastal area with high salt atmosphere. - Aesthetic Value

The surface of stainless steel sheet can be flexibly finished with a wide variety of methods and styles, which look attractive and appealing. People see it as a metal with a shiny surface that provides a sense of elegance and aesthetics. Stainless steel is the perfect option for ornamental and functional purposes, and it has become more and more popular, as it can stand the test of time for long-lasting use, and it’s also a material that is highly compatible with most other materials and furnishing styles. - Heat & Fire Resistant

Stainless steel has excellent resistance to the heat & fire, as its alloying element like chromium makes it more resistant to oxidation, even if it’s in a condition with high temperatures, this allows it to effectively keep its shape and form well at a high temperatures. Stainless steel sheet is much better than other materials in this regard, and is a great option for environment where requires fire and heat resistance, such as commercial kitchens and food processing factories. - Hygiene

Some environments with hygiene and sanitary requirements, such as hospitals, laboratories, or healthcare centers, widely use tools and facilities that are majorly made of stainless steel. As it’s extremely easy to clean and sterilize, and bacteria and grime are not easy to grow on the surface of it, you only need to simply use some detergent or cleaner to swab and polish to make it clear and shine. Stainless steel allows users to easily and conveniently clean and maintain. - Recyclability

Applying stainless steel sheet is a highly sustainable option, since that it’s a totally recyclable type of material. the scrap of stainless steel can be collected for reutilization once it has stopped its original function, In fact, most stainless steel products are made from recycled scrapped material. Unlike some other materials, recycling scrapped stainless steel doesn’t need chemical substances for procession, and some rarer elements don’t need to be added for the combination of alloy. So stainless steel is one of the regenerative resources that can avoid the scarcity of resources and protect the environments from being polluted.

- High Strength & Durability

Stainless steel sheet provides high resistance to impact and wear due to its high strength and toughness. Without much material being used, it can achieve the durable effect, and its shape and form can be kept in good condition even in great pressure. At high or low temperatures. stainless steel comes with low susceptibility to brittleness to allow it to be used without limit. Its outstanding malleability make it easy to be fabricated and formed. - Corrosion & Rust Resistant

As stainless steel sheet has a unique alloying combination that can extremely resist to corrosion and prevent rust. The element of chromium inside is the essential factor that provides stainless steel this property. The invention or discovery of stainless was regarded as the major breakthrough in steel development. Stainless steel can be made with various alloying proportions to provide different properties and grades for different purposes. For example, some types of stainless steel consist of certain amount of molybdenum for resisting to industrial acids and alkaline with high corrosion, and some types are particularly used for coastal area with high salt atmosphere. - Aesthetic Value

The surface of stainless steel sheet can be flexibly finished with a wide variety of methods and styles, which look attractive and appealing. People see it as a metal with a shiny surface that provides a sense of elegance and aesthetics. Stainless steel is the perfect option for ornamental and functional purposes, and it has become more and more popular, as it can stand the test of time for long-lasting use, and it’s also a material that is highly compatible with most other materials and furnishing styles. - Heat & Fire Resistant

Stainless steel has excellent resistance to the heat & fire, as its alloying element like chromium makes it more resistant to oxidation, even if it’s in a condition with high temperatures, this allows it to effectively keep its shape and form well at a high temperatures. Stainless steel sheet is much better than other materials in this regard, and is a great option for environment where requires fire and heat resistance, such as commercial kitchens and food processing factories. - Hygiene

Some environments with hygiene and sanitary requirements, such as hospitals, laboratories, or healthcare centers, widely use tools and facilities that are majorly made of stainless steel. As it’s extremely easy to clean and sterilize, and bacteria and grime are not easy to grow on the surface of it, you only need to simply use some detergent or cleaner to swab and polish to make it clear and shine. Stainless steel allows users to easily and conveniently clean and maintain. - Recyclability

Applying stainless steel sheet is a highly sustainable option, since that it’s a totally recyclable type of material. the scrap of stainless steel can be collected for reutilization once it has stopped its original function, In fact, most stainless steel products are made from recycled scrapped material. Unlike some other materials, recycling scrapped stainless steel doesn’t need chemical substances for procession, and some rarer elements don’t need to be added for the combination of alloy. So stainless steel is one of the regenerative resources that can avoid the scarcity of resources and protect the environments from being polluted.

Trusted Partners

Armour Cladding is proud to have created several stable and long-term relationships with various partners to ensure we provide you with the greatest product and value possible.

Trusted Partners

Armour Cladding is proud to have created several stable and long-term relationships with various partners to ensure we provide you with the greatest product and value possible.